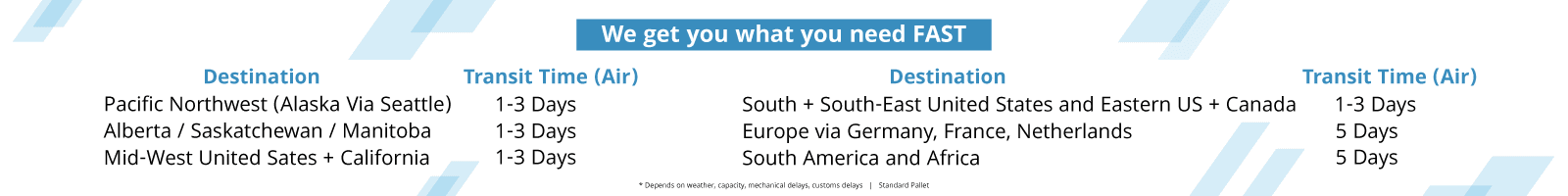

Fast worldwide shipping

Up to 30-40% less expensive than the competition

Up to 25% more efficient pumps than the competition

We can replace Warman® and Metso® mill liners and wear plates

Backed by our leading guarantee

Made in Canada. Custom orders & ready to ship pumps & parts available

Exceptional customer service

Increase Wear Life – Reduce Downtime

ICS Wear Group is committed to providing you with innovative solutions to the challenges associated with handling bulk material on your conveyor belts and similar systems.

Our material and design combinations help to protect your chutes and liners from premature failure often caused by erosion, impact, and abrasion. This leads to increased mill efficiency while prioritizing worker safety.

Check out ICS-200 for a quick fix.

Available Types

- Sag Mill Liners

- Ball Mill Liners

- Re-Grind liners

- Rod Liners

- Custom Solutions

Liner Materials

ICS Wear Group offers liners in a wide combination of materials, sizes, and thicknesses that are all designed to absorb and dissipate impact while promoting increased wear life at the critical wear areas of your chutes. Work-hardened materials from ICS Wear Group will dramatically increase operation time between change outs, which in turn improves worker safety. When combined with clever design to ensure material is thickest where it’s needed without consuming internal volume, you get an exceptional end product.

ICS Rubber Liners – Last Twice as Long

ICS Wear Group also offers customized liners designed for the optimal wear life, tensile strength, and tear resistance to fit your site specific application. Field studies have shown our liners to last upwards of 200% longer than other leading rubber liners using materials under similar operating conditions.

ICS High Performance CR Plate

Also available is the ICS High Performance CR Plate – a combination of high alumina ceramic with the impact absorbing properties of ICS’s Natural Reinforced Infused rubber (NRI). The absorbing qualities of the plate are designed in a manner that places rubber between the bottom of the ceramic and a steel backing plate, ensuring that the abrasion resistant ceramic is protected from impact damage by the shock absorbing NRI Rubber. All CR Liners are designed to fit specified mounting holes, countersunk for a correct fit every time.

Endless Design Options

ICS Wear Group offers liners in a wide combination of materials, sizes, and thicknesses that are all designed to absorb and dissipate impact while promoting increased wear life at the critical wear areas of your chutes. Work-hardened materials from ICS Wear Group will dramatically increase operation time between change outs, which in turn improves worker safety. When combined with clever design to ensure material is thickest where it’s needed without consuming internal volume, you get an exceptional end product.

Endless Design Options

ICS Wear Group offers liners in a wide combination of materials, sizes, and thicknesses that are all designed to absorb and dissipate impact while promoting increased wear life at the critical wear areas of your chutes. Work-hardened materials from ICS Wear Group will dramatically increase operation time between change outs, which in turn improves worker safety. When combined with clever design to ensure material is thickest where it’s needed without consuming internal volume, you get an exceptional end product.

Our Customers Love Us, Here’s What Some of Them Are Saying:

Complete the form below to connect with our expert technicians

We have ready to ship parts in stock or we can provide custom manufactured components made to order. Submit the form below and our technicians will contact you to discuss your needs. Shipping Worldwide!